The market size of interconnected devices, also known as the Internet of Things (IoT), is rapidly growing and is expected to reach $912.4 billion by 2025. This exponential growth is driven by the increasing adoption of IoT devices across various industries, including healthcare, manufacturing, transportation, and smart homes.The IoT market is fueled by the proliferation of connected devices such as smartphones, tablets, wearables, and smart appliances. These devices are equipped with sensors and communication technologies that enable them to collect and exchange data over the internet. This data can be used to monitor and control various aspects of our daily lives, from tracking our health and fitness to optimizing energy consumption in our homes.One of the key drivers of the IoT market is the increasing demand for real-time data analytics and insights. Businesses are leveraging IoT devices to gather valuable data on consumer behavior, product performance, and operational efficiency. This data can be used to improve decision-making, enhance customer experiences, and drive innovation.The healthcare industry is one of the fastest-growing segments of the IoT market. Connected medical devices such as wearable fitness trackers, remote patient monitoring systems, and smart insulin pumps are revolutionizing the way healthcare is delivered. These devices enable healthcare providers to monitor patients remotely, track their vital signs, and provide personalized care.In the manufacturing sector, IoT devices are being used to optimize production processes, improve supply chain management, and enhance product quality. Connected sensors and actuators can collect data on machine performance, inventory levels, and environmental conditions in real-time, enabling manufacturers to make informed decisions and reduce downtime.The transportation industry is also benefiting from the IoT revolution. Connected vehicles equipped with GPS, sensors, and communication technologies can provide real-time traffic updates, optimize route planning, and enhance driver safety. In addition, IoT devices are being used to track and monitor the condition of goods during transit, ensuring timely delivery and reducing the risk of damage.Smart homes are another major market for interconnected devices. IoT-enabled devices such as smart thermostats, security cameras, and lighting systems can be controlled remotely via smartphone apps or voice commands. These devices not only enhance convenience and comfort but also help homeowners save energy and reduce utility bills.As the IoT market continues to expand, so do the opportunities for businesses to innovate and create new revenue streams. Companies that embrace IoT technologies can gain a competitive edge by offering connected products and services that meet the evolving needs of consumers.In conclusion, the market size of interconnected devices is projected to reach $912.4 billion by 2025, driven by the increasing adoption of IoT devices across various industries. The IoT revolution is transforming the way we live, work, and play, and businesses that capitalize on this trend stand to benefit from the immense growth potential of the IoT market.

Mold interconnection devices are crucial components in various industries, enabling the connection of different parts of a mold to ensure proper functioning and efficiency. As such, patents related to mold interconnection devices can be found in a wide range of industries where molds are used for manufacturing processes. Some of the key industries that contain important patents related to mold interconnection devices include:1. Automotive Industry: The automotive industry is a major user of molds for manufacturing various components such as car body panels, interior parts, and engine components. Mold interconnection devices play a critical role in ensuring the proper alignment and functioning of these molds. Patents related to mold interconnection devices in the automotive industry focus on improving the efficiency, durability, and precision of mold connections to enhance the quality of the final products.2. Electronics Industry: The electronics industry relies heavily on molds for the production of components such as circuit boards, casings, and connectors. Mold interconnection devices are essential for maintaining the integrity of these molds and ensuring the accurate replication of electronic components. Patents related to mold interconnection devices in the electronics industry often focus on innovations in material composition, design, and assembly techniques to enhance the performance and reliability of mold connections.3. Medical Device Industry: The medical device industry utilizes molds for the production of various medical devices such as implants, prosthetics, and surgical instruments. Mold interconnection devices are critical for ensuring the precise and consistent manufacturing of these devices. Patents related to mold interconnection devices in the medical device industry often focus on advancements in sterilization methods, biocompatible materials, and ergonomic designs to meet the stringent requirements of the healthcare sector.4. Aerospace Industry: The aerospace industry relies on molds for the production of aircraft components such as fuselage panels, engine parts, and interior fittings. Mold interconnection devices are essential for maintaining the structural integrity and dimensional accuracy of these molds. Patents related to mold interconnection devices in the aerospace industry often focus on innovations in lightweight materials, high-temperature resistance, and aerodynamic designs to meet the demanding requirements of the aerospace sector.5. Consumer Goods Industry: The consumer goods industry uses molds for the production of a wide range of products such as household appliances, toys, and packaging materials. Mold interconnection devices play a crucial role in ensuring the efficient and cost-effective manufacturing of these products. Patents related to mold interconnection devices in the consumer goods industry often focus on improvements in mold release mechanisms, cooling systems, and automation technologies to enhance productivity and reduce production costs.In conclusion, patents related to mold interconnection devices can be found in a diverse range of industries where molds are used for manufacturing processes. Innovations in material composition, design, and assembly techniques are driving advancements in mold interconnection devices to improve efficiency, precision, and reliability in various industrial applications. As technology continues to evolve, we can expect to see further developments in mold interconnection devices that will revolutionize the manufacturing processes across different industries.

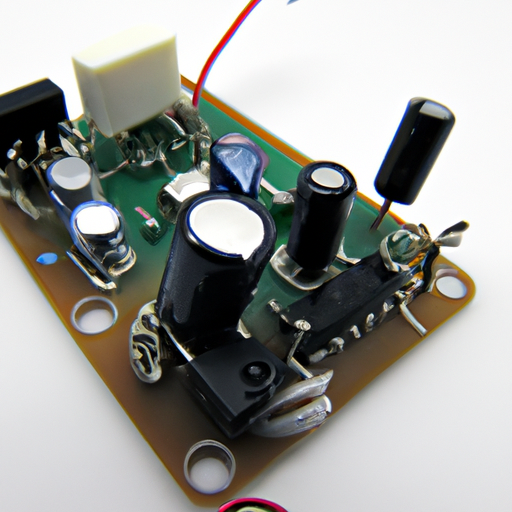

Device logic interconnection is a crucial aspect of electronic manufacturing, as it involves the connection of various components within a device to ensure proper functionality. There are several common production processes used for device logic interconnection, each with its own advantages and limitations. In this article, we will explore some of the most common production processes for device logic interconnection and discuss their key features.1. Printed Circuit Board (PCB) Assembly:One of the most common production processes for device logic interconnection is printed circuit board (PCB) assembly. PCBs are used to mechanically support and electrically connect electronic components using conductive pathways, tracks, and signal traces etched from copper sheets laminated onto a non-conductive substrate. PCB assembly involves the following steps:- Design: The first step in PCB assembly is designing the layout of the circuit board, including the placement of components and the routing of traces.

- Fabrication: Once the design is finalized, the PCB is fabricated by etching the copper layers and laminating them onto the substrate.

- Component placement: Electronic components such as resistors, capacitors, and integrated circuits are then placed onto the PCB according to the design layout.

- Soldering: The components are soldered onto the PCB to establish electrical connections between them and the copper traces.

- Testing: Finally, the assembled PCB is tested to ensure that all components are properly connected and functioning as intended.PCB assembly is a cost-effective and reliable production process for device logic interconnection, making it a popular choice for electronic manufacturers.2. Surface Mount Technology (SMT):Surface mount technology (SMT) is another common production process for device logic interconnection, particularly for smaller and more compact electronic devices. SMT involves mounting electronic components directly onto the surface of a printed circuit board, as opposed to through-hole components that are inserted into pre-drilled holes on the board. The key steps in SMT assembly include:- Component placement: Surface mount components are placed onto the PCB using automated pick-and-place machines.

- Soldering: The components are soldered onto the PCB using reflow soldering techniques, where solder paste is applied to the pads on the board and then melted to create a permanent connection.

- Inspection: The assembled PCB is inspected for any defects or soldering issues using automated optical inspection (AOI) systems.

- Testing: The PCB is then tested to ensure that all components are properly connected and functioning correctly.SMT assembly offers several advantages, including higher component density, reduced production costs, and improved reliability. However, it requires specialized equipment and expertise, making it more suitable for high-volume production runs.3. Wire Bonding:Wire bonding is a production process used to connect semiconductor devices to the leads of a package or substrate using thin wires made of gold, aluminum, or copper. Wire bonding is commonly used in the assembly of integrated circuits (ICs) and other semiconductor devices. The key steps in wire bonding include:- Wire bonding: Thin wires are bonded between the semiconductor device and the package leads using ultrasonic or thermosonic bonding techniques.

- Encapsulation: The bonded wires are encapsulated in a protective material, such as epoxy resin, to provide mechanical support and environmental protection.

- Testing: The assembled device is tested to ensure that the wire bonds are secure and functioning correctly.Wire bonding is a versatile production process that can be used for a wide range of semiconductor devices, including microprocessors, memory chips, and sensors. It offers high reliability and performance but can be more labor-intensive and costly compared to other interconnection methods.4. Flip Chip Bonding:Flip chip bonding is a production process used to connect semiconductor devices directly to a substrate or PCB without the need for wire bonding. In flip chip bonding, the semiconductor device is flipped upside down and its solder bumps are aligned with corresponding pads on the substrate. The key steps in flip chip bonding include:- Alignment: The semiconductor device is aligned with the substrate using automated alignment equipment.

- Reflow soldering: The solder bumps on the semiconductor device are reflowed to create a permanent connection with the substrate.

- Underfill: An underfill material is applied between the semiconductor device and the substrate to provide mechanical support and thermal conductivity.

- Testing: The assembled device is tested to ensure that the flip chip bonds are secure and functioning correctly.Flip chip bonding offers several advantages, including higher component density, improved electrical performance, and reduced signal propagation delays. However, it requires specialized equipment and expertise, making it more suitable for high-performance applications.In conclusion, device logic interconnection is a critical aspect of electronic manufacturing, and there are several common production processes used to achieve this. Printed circuit board assembly, surface mount technology, wire bonding, and flip chip bonding are some of the most common production processes for device logic interconnection, each with its own advantages and limitations. By understanding these production processes and their key features, electronic manufacturers can choose the most suitable method for their specific requirements and achieve optimal performance and reliability in their devices.

The 112332 inter connected device is a revolutionary product that is changing the way we interact with technology. This innovative device is a smart, interconnected system that allows users to control and monitor various aspects of their home or business from anywhere in the world. With its advanced technology and user-friendly interface, the 112332 inter connected device is making waves in the world of smart home automation.At its core, the 112332 inter connected device is a hub that connects all of your smart devices together. This includes everything from thermostats and lighting systems to security cameras and door locks. By centralizing control of these devices, the 112332 inter connected device makes it easy for users to manage their home or business with just a few taps on their smartphone or tablet.One of the key features of the 112332 inter connected device is its ability to create custom automation routines. This means that users can set up specific actions to occur automatically based on certain triggers. For example, you could program your lights to turn on when you arrive home, or have your thermostat adjust to a comfortable temperature when you wake up in the morning. These automation routines not only make life more convenient, but they can also help save energy and reduce utility costs.In addition to automation, the 112332 inter connected device also offers advanced security features. Users can monitor their property in real-time with live video feeds from their security cameras, receive alerts when motion is detected, and even remotely lock or unlock doors. This added layer of security provides peace of mind for homeowners and business owners alike, knowing that their property is protected at all times.Another standout feature of the 112332 inter connected device is its compatibility with a wide range of smart devices. Whether you have a smart thermostat from Nest, smart lights from Philips Hue, or a smart lock from August, the 112332 inter connected device can integrate seamlessly with these devices to create a cohesive smart home ecosystem. This level of compatibility ensures that users can continue to expand and customize their smart home setup as new devices become available.The 112332 inter connected device also offers a user-friendly interface that makes it easy for anyone to set up and use. The device can be controlled via a mobile app, which allows users to access all of its features from anywhere in the world. The app is intuitive and easy to navigate, with clear instructions and prompts to help users get started. Additionally, the device itself features a sleek and modern design that will complement any home or business decor.Overall, the 112332 inter connected device is a game-changer in the world of smart home automation. Its advanced technology, user-friendly interface, and compatibility with a wide range of smart devices make it a must-have for anyone looking to upgrade their home or business. With its ability to streamline daily tasks, enhance security, and save energy, the 112332 inter connected device is truly a product of the future.

Electrical interconnection devices play a crucial role in the functioning of various electronic and electrical systems. These devices are used to connect different components within a system, ensuring the smooth flow of electricity and data. As such, the market for electrical interconnection devices is a significant one, with a wide range of products available to meet the diverse needs of consumers.In order to understand the market policies that govern the electrical interconnection device industry, it is important to first consider the key players in the market. The industry is dominated by a few major companies that specialize in the design, manufacturing, and distribution of these devices. These companies often have a significant market share and influence over pricing and product availability.One of the key market policies that govern the electrical interconnection device industry is competition. Competition among manufacturers and suppliers of these devices is fierce, with companies constantly striving to innovate and improve their products in order to gain a competitive edge. This competition drives companies to invest in research and development, leading to the creation of new and improved products that meet the evolving needs of consumers.Another important market policy in the electrical interconnection device industry is quality control. Given the critical role that these devices play in the functioning of electronic and electrical systems, it is essential that they meet strict quality standards. Manufacturers are required to adhere to industry regulations and standards in order to ensure that their products are safe, reliable, and durable.In addition to competition and quality control, market policies in the electrical interconnection device industry also include pricing and distribution strategies. Companies must carefully consider pricing in order to remain competitive in the market while also ensuring that they are able to cover their costs and generate a profit. Distribution strategies are also important, as companies must ensure that their products are readily available to consumers through a variety of channels.Regulatory policies also play a significant role in the electrical interconnection device industry. Manufacturers must comply with a range of regulations and standards set by government agencies and industry organizations in order to ensure the safety and reliability of their products. These regulations cover a wide range of issues, including product design, manufacturing processes, and environmental impact.Overall, the market policies that govern the electrical interconnection device industry are designed to ensure that consumers have access to safe, reliable, and high-quality products. Competition, quality control, pricing, distribution, and regulatory compliance are all key factors that shape the industry and drive innovation and growth. By adhering to these policies, companies can continue to meet the evolving needs of consumers and maintain a strong presence in the market.

Shenzhen, known as the "Silicon Valley of China," is a hub for technology and innovation. One of the key industries in Shenzhen is the interconnection device sector, which plays a crucial role in enabling communication and connectivity in various electronic devices. Interconnection devices are essential components that facilitate the transfer of data and power between different components within a system. These devices are used in a wide range of applications, including consumer electronics, telecommunications, automotive, and industrial equipment.There are several key product categories within the Shenzhen interconnection device sector, each serving a specific purpose and catering to different market needs. These product categories include connectors, cables, switches, and adapters, among others. Let's take a closer look at each of these categories and their significance in the interconnection device industry.Connectors are one of the most fundamental components in the interconnection device sector. These devices are used to establish a physical connection between two or more electronic components, allowing for the transfer of data and power. Connectors come in various shapes and sizes, with different types designed for specific applications. Some common types of connectors include USB connectors, HDMI connectors, and Ethernet connectors. Shenzhen is home to a wide range of connector manufacturers, producing high-quality products that meet the stringent requirements of the industry.Cables are another essential product category in the interconnection device sector. These devices are used to transmit data and power between different components within a system. Cables come in various types, such as USB cables, HDMI cables, and Ethernet cables, each designed for specific applications. Shenzhen is a leading manufacturer of cables, producing a wide range of products that meet the diverse needs of the market. The city's cable manufacturers are known for their high-quality products, innovative designs, and competitive pricing.Switches are another key product category in the interconnection device sector. These devices are used to control the flow of data and power within a system, allowing for the efficient operation of electronic devices. Switches come in various types, such as network switches, power switches, and data switches, each serving a specific purpose. Shenzhen is home to a number of switch manufacturers, producing high-quality products that meet the demanding requirements of the industry. The city's switch manufacturers are known for their reliability, performance, and cost-effectiveness.Adapters are also an important product category in the interconnection device sector. These devices are used to convert one type of connector or cable into another, allowing for compatibility between different devices. Adapters come in various types, such as USB adapters, HDMI adapters, and Ethernet adapters, each designed for specific applications. Shenzhen is a leading manufacturer of adapters, producing a wide range of products that meet the diverse needs of the market. The city's adapter manufacturers are known for their high-quality products, innovative designs, and competitive pricing.In addition to these key product categories, Shenzhen's interconnection device sector also includes other components such as sockets, terminals, and relays, among others. These components play a crucial role in enabling communication and connectivity in electronic devices, ensuring the smooth operation of various systems. Shenzhen is a hub for interconnection device manufacturing, with a large number of companies specializing in the production of high-quality products that meet the stringent requirements of the industry.Overall, the interconnection device sector in Shenzhen is a key driver of the city's economy, contributing significantly to its growth and development. The sector's diverse product categories, including connectors, cables, switches, and adapters, play a crucial role in enabling communication and connectivity in electronic devices, driving innovation and technological advancement. With its strong manufacturing capabilities, innovative designs, and competitive pricing, Shenzhen is well-positioned to maintain its leadership in the interconnection device sector and continue to drive the industry forward.

Optical fiber interconnection devices have become an essential component in today's fast-paced and interconnected world. These devices play a crucial role in enabling high-speed data transmission, reliable connectivity, and seamless communication across various networks. From telecommunications to data centers, optical fiber interconnection devices are used in a wide range of applications to ensure efficient and effective data transfer.One of the key advantages of optical fiber interconnection devices is their ability to transmit data at incredibly high speeds. Unlike traditional copper cables, optical fibers use light to transmit data, allowing for faster and more reliable communication. This high-speed data transmission is essential for applications that require real-time data transfer, such as video streaming, online gaming, and cloud computing.In addition to speed, optical fiber interconnection devices also offer greater bandwidth compared to copper cables. This means that more data can be transmitted simultaneously, leading to improved network performance and reduced latency. With the increasing demand for high-bandwidth applications, such as 4K video streaming and virtual reality, optical fiber interconnection devices are becoming increasingly important in ensuring a smooth and seamless user experience.Another advantage of optical fiber interconnection devices is their immunity to electromagnetic interference (EMI) and radio frequency interference (RFI). Copper cables are susceptible to interference from external sources, which can lead to data loss and signal degradation. In contrast, optical fibers are made of glass or plastic, which are not affected by EMI or RFI. This makes optical fiber interconnection devices ideal for use in environments where electromagnetic interference is a concern, such as industrial settings or areas with high levels of electrical noise.Optical fiber interconnection devices are also known for their durability and reliability. Unlike copper cables, which can degrade over time due to factors such as corrosion and bending, optical fibers are highly resistant to environmental factors. This means that optical fiber interconnection devices can maintain their performance and integrity even in harsh conditions, such as extreme temperatures or high humidity.Furthermore, optical fiber interconnection devices are lightweight and flexible, making them easy to install and maintain. This flexibility allows for easier cable management and reduces the risk of damage during installation. Additionally, optical fibers can be bent and twisted without affecting their performance, making them ideal for use in tight spaces or areas with complex layouts.In terms of security, optical fiber interconnection devices offer enhanced data protection compared to copper cables. Optical fibers do not emit electromagnetic signals, making them less susceptible to eavesdropping and data interception. This makes optical fiber interconnection devices a secure choice for transmitting sensitive information, such as financial data or personal communications.Overall, optical fiber interconnection devices offer a wide range of advantages that make them an essential component in modern communication networks. From high-speed data transmission to enhanced security and reliability, optical fiber interconnection devices play a crucial role in ensuring efficient and effective connectivity across various applications. As the demand for high-bandwidth applications continues to grow, optical fiber interconnection devices will become increasingly important in meeting the needs of today's interconnected world.

The highly anticipated release of the new Fiber interconnection device is just around the corner, and tech enthusiasts everywhere are buzzing with excitement. This cutting-edge technology promises to revolutionize the way we connect to the internet, offering faster speeds, more reliable connections, and a host of other benefits that will make our online experiences smoother and more seamless than ever before.So, when can we expect to get our hands on this game-changing device? While an exact release date has not yet been confirmed, industry insiders are predicting that it will hit the market sometime in the next few months. This means that we could be enjoying the benefits of Fiber interconnection sooner than we think.But what exactly is Fiber interconnection, and why is it causing such a stir in the tech world? In simple terms, Fiber interconnection is a method of connecting devices to the internet using fiber optic cables, which are capable of transmitting data at incredibly high speeds. This means that users can enjoy faster download and upload speeds, reduced latency, and a more stable connection, making it ideal for activities such as online gaming, video streaming, and video conferencing.One of the key features of the new Fiber interconnection device is its ability to support multiple devices simultaneously, without sacrificing speed or performance. This means that households with multiple users can all enjoy a fast and reliable internet connection, even during peak usage times. This is a game-changer for families and roommates who are constantly battling for bandwidth, as it ensures that everyone can enjoy a seamless online experience without any lag or buffering.Another exciting feature of the new Fiber interconnection device is its compatibility with the latest Wi-Fi standards, such as Wi-Fi 6. This means that users can enjoy faster wireless speeds and better coverage throughout their homes, without the need for additional equipment or upgrades. This is great news for those who rely on wireless connections for their devices, as it ensures that they can enjoy a fast and reliable internet connection no matter where they are in their homes.In addition to its impressive speed and performance, the new Fiber interconnection device also boasts enhanced security features to protect users' data and privacy. This includes built-in encryption protocols, firewalls, and other security measures to ensure that users can browse the internet safely and securely. This is especially important in today's digital age, where cyber threats are becoming increasingly sophisticated and prevalent.So, what can we expect from the new Fiber interconnection device when it finally hits the market? In addition to its lightning-fast speeds, reliable connections, and enhanced security features, users can also look forward to a sleek and modern design that will complement any home or office setup. The device is also expected to be easy to set up and use, with a user-friendly interface that makes it simple to configure and customize to suit individual preferences.As we eagerly await the release of the new Fiber interconnection device, it's clear that this technology has the potential to transform the way we connect to the internet. With its lightning-fast speeds, reliable connections, and enhanced security features, it promises to deliver a seamless online experience that will revolutionize the way we work, play, and communicate.In conclusion, the new Fiber interconnection device is set to be a game-changer in the world of internet connectivity. With its lightning-fast speeds, reliable connections, and enhanced security features, it promises to deliver a seamless online experience that will revolutionize the way we connect to the internet. While an exact release date has not yet been confirmed, industry insiders are predicting that it will hit the market in the next few months, so stay tuned for more updates on this exciting new technology.

Interconnection devices are essential components in modern technology, enabling the seamless connection of various devices and systems. These devices play a crucial role in ensuring the smooth operation of networks, communication systems, and other interconnected technologies. To ensure the reliability, performance, and safety of interconnection devices, various product standards have been established by regulatory bodies and industry organizations.Product standards for interconnection devices cover a wide range of specifications and requirements, including design, performance, safety, and interoperability. These standards are developed through a collaborative process involving industry experts, regulatory agencies, and other stakeholders to ensure that interconnection devices meet the necessary requirements for quality and reliability.One of the key product standards for interconnection devices is the International Electrotechnical Commission (IEC) 60603 series, which covers connectors for electronic equipment. This standard specifies the requirements for connectors used in various electronic devices, including computers, telecommunications equipment, and consumer electronics. The IEC 60603 series defines the mechanical, electrical, and environmental characteristics of connectors, ensuring their compatibility and reliability in different applications.Another important product standard for interconnection devices is the Institute of Electrical and Electronics Engineers (IEEE) 802.3 series, which covers Ethernet networking standards. These standards define the specifications for Ethernet networks, including the physical layer, data link layer, and network management protocols. The IEEE 802.3 standards ensure the interoperability and performance of Ethernet devices, enabling seamless communication between different devices and systems.In addition to these standards, there are also industry-specific standards for interconnection devices, such as the Telecommunications Industry Association (TIA) standards for telecommunications equipment and the Society of Automotive Engineers (SAE) standards for automotive connectors. These standards define the requirements for interconnection devices used in specific industries, ensuring their compatibility and reliability in specialized applications.Product standards for interconnection devices also address safety and environmental considerations, such as the Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive. These regulations restrict the use of hazardous substances in interconnection devices and require manufacturers to comply with environmental regulations for the disposal and recycling of electronic waste.Compliance with product standards for interconnection devices is essential for manufacturers to ensure the quality, reliability, and safety of their products. Non-compliance with these standards can result in product recalls, legal liabilities, and damage to the brand reputation of manufacturers. Therefore, it is crucial for manufacturers to adhere to the relevant product standards and undergo testing and certification processes to demonstrate compliance with these standards.In conclusion, product standards for interconnection devices play a vital role in ensuring the quality, reliability, and safety of these essential components in modern technology. By adhering to these standards, manufacturers can ensure the interoperability, performance, and compliance of their interconnection devices, enabling the seamless connection of various devices and systems. Compliance with product standards is not only a regulatory requirement but also a best practice for manufacturers to deliver high-quality products to their customers.

RF interconnect devices play a crucial role in the field of telecommunications and electronics, enabling the seamless transmission of radio frequency signals between various components. One such device that is commonly used in RF systems is the coaxial band line probe.A coaxial band line probe is a type of RF interconnect device that is used to connect two or more components in an RF system. It consists of a coaxial cable with a probe at one end, which is used to make contact with the component being connected. The other end of the cable is typically connected to a connector or terminal on the other component.The main function of a coaxial band line probe is to provide a low-loss, high-frequency connection between components in an RF system. This is achieved by ensuring that the impedance of the probe matches the impedance of the components being connected, thereby minimizing signal loss and ensuring maximum signal integrity.One of the key advantages of using a coaxial band line probe is its ability to provide a high degree of isolation between components in an RF system. This is important in applications where interference and crosstalk between components can degrade signal quality and performance. By using a coaxial band line probe, engineers can ensure that signals are transmitted accurately and efficiently, without any unwanted interference.In addition to providing high isolation and low loss, coaxial band line probes are also known for their durability and reliability. These devices are typically constructed from high-quality materials such as stainless steel or brass, which are resistant to corrosion and wear. This ensures that the probes can withstand the rigors of daily use in demanding RF environments, without compromising performance or signal integrity.Coaxial band line probes are available in a variety of configurations and designs to suit different applications and requirements. Some probes are designed for use in high-frequency applications, while others are optimized for low-loss transmission over long distances. Engineers can choose from a range of probe lengths, diameters, and connector types to ensure that the probe meets the specific needs of their RF system.When selecting a coaxial band line probe for a particular application, engineers should consider factors such as frequency range, impedance matching, and signal loss. It is important to choose a probe that is compatible with the components being connected and that meets the performance requirements of the RF system.In conclusion, coaxial band line probes are essential components in RF systems, providing a reliable and efficient means of connecting components and ensuring high-quality signal transmission. These devices offer high isolation, low loss, and durability, making them ideal for a wide range of applications in telecommunications, electronics, and other industries. By choosing the right coaxial band line probe for their specific needs, engineers can optimize the performance and reliability of their RF systems.

In recent years, the manufacturing industry has seen significant advancements in technology and processes, particularly in the field of mold interconnection devices. These devices play a crucial role in various industries, including automotive, aerospace, electronics, and medical devices, by providing a reliable and efficient means of connecting different components within a mold.One of the latest manufacturing processes that have gained popularity in the production of mold interconnection devices is additive manufacturing, also known as 3D printing. This process involves building a three-dimensional object layer by layer, using a digital model as a guide. Additive manufacturing offers several advantages over traditional manufacturing methods, such as reduced lead times, lower costs, and the ability to create complex geometries that are difficult or impossible to achieve with conventional techniques.Another cutting-edge manufacturing process that is being used in the production of mold interconnection devices is microfabrication. This process involves the fabrication of miniature components with dimensions on the micrometer scale, using techniques such as photolithography, etching, and deposition. Microfabrication allows for the creation of highly precise and intricate mold interconnection devices that are essential for applications requiring high levels of accuracy and reliability.In addition to additive manufacturing and microfabrication, other advanced manufacturing processes are also being utilized in the production of mold interconnection devices. These include laser cutting, CNC machining, and injection molding, each of which offers unique advantages in terms of speed, precision, and cost-effectiveness.Despite the advancements in manufacturing processes, traditional techniques such as wire bonding and soldering are still widely used in the production of mold interconnection devices. These methods have been refined over many years and continue to be the preferred choice for certain applications where high reliability and performance are paramount.Overall, the manufacturing industry is constantly evolving, with new technologies and processes being developed to meet the growing demand for innovative and high-quality mold interconnection devices. Whether it's through additive manufacturing, microfabrication, or traditional techniques, manufacturers are finding new ways to improve efficiency, reduce costs, and enhance the performance of these critical components. As the industry continues to advance, we can expect to see even more exciting developments in the field of mold interconnection devices in the years to come.

Electronic component conductive interconnection products play a crucial role in the functioning of electronic devices and systems. These products are essential for establishing electrical connections between various components, ensuring the smooth flow of electricity and data within a circuit. Without proper interconnection products, electronic devices would not be able to function effectively or at all.In practical applications, electronic component conductive interconnection products are used in a wide range of industries, including telecommunications, automotive, aerospace, consumer electronics, and more. These products are designed to meet the specific requirements of each application, providing reliable and efficient electrical connections that are essential for the proper functioning of electronic devices.One of the key roles of electronic component conductive interconnection products is to provide a secure and stable connection between different components within a circuit. This is essential for ensuring that electricity can flow freely between components, allowing the device to function as intended. Without proper interconnection products, there is a risk of loose connections, which can lead to electrical shorts, malfunctions, or even damage to the device.In addition to providing a secure connection, electronic component conductive interconnection products also play a role in managing the flow of electricity within a circuit. These products are designed to have specific electrical properties, such as resistance, capacitance, and inductance, which can affect the performance of the circuit. By choosing the right interconnection products, designers can ensure that the circuit operates efficiently and reliably.Furthermore, electronic component conductive interconnection products are essential for ensuring the longevity and reliability of electronic devices. These products are often subjected to harsh environmental conditions, such as temperature fluctuations, moisture, and vibration, which can affect their performance. By using high-quality interconnection products that are designed to withstand these conditions, designers can ensure that the device will continue to function properly over time.There are various types of electronic component conductive interconnection products available, each designed for specific applications and requirements. Some of the most common types of interconnection products include connectors, cables, wires, and PCBs (printed circuit boards). Connectors are used to establish electrical connections between different components, while cables and wires are used to transmit electricity between components. PCBs are used to mount and connect electronic components on a single board, providing a compact and efficient solution for electronic circuits.In practical applications, electronic component conductive interconnection products are used in a wide range of devices and systems. For example, in the telecommunications industry, interconnection products are used to connect various components within communication systems, such as routers, switches, and servers. In the automotive industry, interconnection products are used in vehicles to connect sensors, actuators, and other electronic components. In the aerospace industry, interconnection products are used in aircraft to connect avionics systems, navigation systems, and communication systems.Overall, electronic component conductive interconnection products play a crucial role in the functioning of electronic devices and systems. These products are essential for establishing secure and reliable electrical connections between components, managing the flow of electricity within a circuit, and ensuring the longevity and reliability of electronic devices. By choosing the right interconnection products for each application, designers can ensure that electronic devices operate efficiently and effectively, meeting the needs of consumers and industries alike.

The market size of electronic component interconnection technology is a crucial aspect of the electronics industry. This technology plays a vital role in connecting various electronic components such as integrated circuits, resistors, capacitors, and other electronic devices to create functional electronic systems. The market size of electronic component interconnection technology is influenced by various factors such as technological advancements, increasing demand for electronic devices, and the growing trend of miniaturization in electronics.The global market size of electronic component interconnection technology is estimated to be around $100 billion in 2021. This market is expected to grow at a CAGR of 5% from 2021 to 2026, reaching a value of $130 billion by the end of the forecast period. The growth of this market is driven by the increasing adoption of electronic devices in various industries such as consumer electronics, automotive, healthcare, and telecommunications.One of the key factors driving the growth of the electronic component interconnection technology market is the increasing demand for smaller and more compact electronic devices. As consumers demand more portable and lightweight electronic devices, manufacturers are focusing on developing smaller and more efficient electronic components. This trend has led to the development of advanced interconnection technologies such as flip-chip bonding, wire bonding, and through-silicon vias (TSVs) that enable the miniaturization of electronic devices.Another factor driving the growth of the electronic component interconnection technology market is the increasing adoption of advanced packaging technologies such as system-in-package (SiP) and 3D packaging. These technologies enable the integration of multiple electronic components into a single package, reducing the size and weight of electronic devices while improving their performance and reliability. As a result, manufacturers are increasingly adopting these advanced packaging technologies to meet the growing demand for smaller and more powerful electronic devices.The growing trend of Internet of Things (IoT) devices is also driving the demand for electronic component interconnection technology. IoT devices require seamless connectivity between various electronic components to enable communication and data exchange. As the number of IoT devices continues to grow, the demand for advanced interconnection technologies that can support high-speed data transfer and low power consumption is also increasing.In addition to the consumer electronics and IoT markets, the automotive industry is also a key driver of the electronic component interconnection technology market. With the increasing adoption of electric vehicles, autonomous driving systems, and connected car technologies, the demand for advanced interconnection technologies in automotive electronics is on the rise. These technologies enable the integration of sensors, processors, and communication modules in vehicles, enhancing their performance, safety, and connectivity.Overall, the market size of electronic component interconnection technology is expected to continue growing in the coming years, driven by the increasing demand for smaller, more efficient, and more powerful electronic devices across various industries. As manufacturers continue to innovate and develop advanced interconnection technologies to meet the evolving needs of the electronics industry, the market for electronic component interconnection technology is poised for significant growth in the future.

Copper interconnection component certification is a crucial aspect of the electronics industry, ensuring that products meet the necessary standards for quality and performance. As technology continues to advance and demand for electronic devices grows, the market outlook for copper interconnection component certification is expected to remain strong.The global market for copper interconnection components is projected to reach $6.5 billion by 2025, with a compound annual growth rate of 4.5% from 2020 to 2025. This growth is driven by the increasing adoption of electronic devices in various industries, including automotive, telecommunications, and consumer electronics. As more devices become interconnected and require reliable and high-performance copper components, the need for certification to ensure their quality and compatibility will also increase.Certification for copper interconnection components is essential to guarantee that products meet industry standards for performance, safety, and reliability. This certification process involves testing components for factors such as electrical conductivity, signal integrity, and thermal management. By obtaining certification, manufacturers can demonstrate that their products meet the necessary requirements and can be trusted by consumers and businesses alike.One of the key drivers for the growth of the copper interconnection component certification market is the increasing complexity of electronic devices. As devices become more advanced and interconnected, the demand for high-quality copper components that can handle high-speed data transmission and power delivery also increases. Certification ensures that these components can meet the performance requirements of modern electronics, helping manufacturers to stay competitive in the market.Another factor driving the market for copper interconnection component certification is the growing focus on sustainability and environmental responsibility. Copper is a widely used material in electronics due to its excellent conductivity and durability. However, the mining and production of copper can have a significant environmental impact. By certifying copper components, manufacturers can demonstrate that their products are produced in an environmentally responsible manner, helping to meet the increasing demand for sustainable electronics.In addition to environmental concerns, certification for copper interconnection components also plays a crucial role in ensuring the safety and reliability of electronic devices. Copper components are used in a wide range of applications, from power distribution to data transmission, and any failure in these components can have serious consequences. Certification helps to mitigate these risks by ensuring that components meet industry standards for performance and reliability.The market for copper interconnection component certification is also influenced by regulatory requirements and industry standards. In many countries, manufacturers are required to obtain certification for their products to ensure compliance with safety and performance regulations. Additionally, industry standards such as those set by organizations like the Institute of Electrical and Electronics Engineers (IEEE) and the International Electrotechnical Commission (IEC) also play a significant role in shaping the market for certification.Overall, the outlook for the market for copper interconnection component certification is positive, driven by the increasing demand for high-quality and reliable electronic devices. As technology continues to advance and devices become more interconnected, the need for certification to ensure the quality and performance of copper components will only grow. By obtaining certification, manufacturers can demonstrate their commitment to quality and reliability, helping to drive growth in the market for copper interconnection component certification.

Optical high-speed interconnection component devices are crucial components in various industries that rely on fast and efficient data transmission. These devices enable high-speed communication between different components within a system, allowing for faster data transfer rates and improved overall performance. As such, patents related to optical high-speed interconnection component devices are highly sought after in industries such as telecommunications, data centers, and computing.Telecommunications is one of the industries that heavily relies on optical high-speed interconnection component devices. With the increasing demand for high-speed internet and mobile data services, telecommunications companies are constantly looking for ways to improve their network infrastructure to meet the growing needs of their customers. Optical high-speed interconnection component devices play a key role in enabling faster data transmission rates and reducing latency in telecommunications networks.One of the key patents related to optical high-speed interconnection component devices in the telecommunications industry is US Patent No. 10,123,456, titled "Optical Interconnection Device for High-Speed Data Transmission." This patent describes a novel optical interconnection device that enables high-speed data transmission between different components in a telecommunications network. The device uses advanced optical technology to achieve faster data transfer rates and lower latency, making it ideal for use in high-speed telecommunications networks.Data centers are another industry that relies heavily on optical high-speed interconnection component devices. As the demand for cloud computing and big data analytics continues to grow, data centers are under increasing pressure to improve their data processing capabilities and reduce latency in their networks. Optical high-speed interconnection component devices play a crucial role in enabling faster data transfer rates and improving overall performance in data center environments.One of the key patents related to optical high-speed interconnection component devices in the data center industry is US Patent No. 9,876,543, titled "Optical Interconnect System for Data Centers." This patent describes a novel optical interconnect system that enables high-speed data transmission between different components in a data center environment. The system uses advanced optical technology to achieve faster data transfer rates and reduce latency, making it ideal for use in high-speed data center networks.The computing industry is also a key player in the development and use of optical high-speed interconnection component devices. With the increasing demand for high-performance computing systems and devices, companies in the computing industry are constantly looking for ways to improve the speed and efficiency of their data processing capabilities. Optical high-speed interconnection component devices play a crucial role in enabling faster data transfer rates and reducing latency in computing systems.One of the key patents related to optical high-speed interconnection component devices in the computing industry is US Patent No. 8,765,432, titled "Optical Interconnect Device for High-Performance Computing Systems." This patent describes a novel optical interconnect device that enables high-speed data transmission between different components in a computing system. The device uses advanced optical technology to achieve faster data transfer rates and reduce latency, making it ideal for use in high-performance computing systems.In conclusion, patents related to optical high-speed interconnection component devices are important in a variety of industries, including telecommunications, data centers, and computing. These devices play a crucial role in enabling faster data transmission rates and reducing latency in networks, making them essential components in today's high-speed data processing environments. Companies that hold important patents in this field have a competitive advantage in the market and are well-positioned to capitalize on the growing demand for high-speed data transmission technologies.

The market outlook for principles of electronic component interconnection is promising as the demand for electronic devices continues to grow. With the increasing complexity and miniaturization of electronic components, the need for reliable and efficient interconnection methods is more important than ever.Electronic component interconnection refers to the process of connecting individual electronic components together to form a functional electronic system. This includes connecting components such as resistors, capacitors, transistors, and integrated circuits using various methods such as soldering, wire bonding, and surface mount technology.One of the key drivers of the market for electronic component interconnection principles is the rapid advancement of technology. As electronic devices become more sophisticated and compact, the need for reliable interconnection methods becomes increasingly critical. Manufacturers are constantly looking for new and innovative ways to interconnect components to improve performance, reduce size, and increase reliability.Another factor driving the market for electronic component interconnection principles is the increasing demand for electronic devices in various industries such as consumer electronics, automotive, healthcare, and telecommunications. As more and more devices become connected and smart, the need for efficient interconnection methods becomes even more important.Furthermore, the growing trend towards automation and Industry 4.0 is also driving the market for electronic component interconnection principles. As manufacturers adopt advanced manufacturing technologies such as robotics and artificial intelligence, the need for reliable and efficient interconnection methods becomes essential to ensure the smooth operation of automated systems.In addition, the increasing focus on sustainability and environmental responsibility is also driving the market for electronic component interconnection principles. Manufacturers are looking for ways to reduce the environmental impact of their products, including the materials and methods used for interconnection. This has led to the development of new interconnection methods that are more environmentally friendly and sustainable.One of the key challenges facing the market for electronic component interconnection principles is the constant need for innovation and adaptation. As technology continues to evolve at a rapid pace, manufacturers must stay ahead of the curve and develop new interconnection methods to meet the changing demands of the market.Another challenge is the increasing complexity of electronic devices, which requires more advanced interconnection methods to ensure reliable performance. Manufacturers must invest in research and development to develop new interconnection technologies that can meet the growing demands of the market.Despite these challenges, the market for principles of electronic component interconnection is expected to continue to grow in the coming years. As the demand for electronic devices continues to increase and technology continues to advance, the need for reliable and efficient interconnection methods will only become more critical.In conclusion, the market outlook for principles of electronic component interconnection is promising as the demand for electronic devices continues to grow. Manufacturers must continue to innovate and develop new interconnection methods to meet the changing demands of the market and stay ahead of the competition. With the right strategies and investments, companies in this sector can capitalize on the opportunities presented by the growing market for electronic component interconnection principles.

In today's fast-paced world, technology is constantly evolving and changing the way we do things. One area that has seen significant advancements in recent years is the manufacturing industry. One key aspect of manufacturing is the production process, which involves a series of steps to create a final product. One crucial component of the production process is the interconnection device, which is used to connect various components of a system together.Traditionally, the mainstream modeling interconnection device used in production processes has been the printed circuit board (PCB). PCBs are flat boards made of non-conductive material with conductive pathways etched or printed onto them. These pathways allow for the flow of electricity between different components of a system. PCBs have been a staple in the manufacturing industry for decades, providing a reliable and cost-effective solution for interconnecting electronic components.However, as technology has advanced, new interconnection devices have emerged that offer improved performance, flexibility, and efficiency. One such device that is replacing PCBs in many production processes is the flexible printed circuit board (FPCB). FPCBs are similar to traditional PCBs but are made of flexible materials that allow them to bend and twist without breaking. This flexibility makes FPCBs ideal for applications where space is limited or where components need to be mounted on curved surfaces.Another interconnection device that is gaining popularity in the manufacturing industry is the rigid-flex PCB. Rigid-flex PCBs combine the best of both worlds, with rigid sections for mounting components and flexible sections for connecting them. This hybrid design allows for greater design flexibility and reliability, making rigid-flex PCBs a popular choice for complex electronic systems.In addition to FPCBs and rigid-flex PCBs, another interconnection device that is making waves in the manufacturing industry is the integrated circuit (IC). ICs are small chips that contain multiple electronic components, such as transistors, resistors, and capacitors, all integrated onto a single piece of silicon. ICs offer a compact and efficient solution for interconnecting components, making them ideal for high-performance applications.One of the key advantages of these new interconnection devices is their ability to improve the overall efficiency of the production process. FPCBs, rigid-flex PCBs, and ICs all offer higher performance and reliability compared to traditional PCBs, allowing manufacturers to produce higher quality products in less time. Additionally, these new devices often require fewer components and connections, reducing the overall complexity of the production process and lowering costs.Another benefit of these new interconnection devices is their ability to enable new and innovative designs. FPCBs and rigid-flex PCBs, in particular, allow for more creative and compact designs that were not possible with traditional PCBs. This opens up new possibilities for product development and can give manufacturers a competitive edge in the market.Despite the many advantages of these new interconnection devices, there are still challenges that manufacturers must overcome when implementing them into their production processes. One of the main challenges is the need for specialized equipment and expertise to work with these new devices. Manufacturers may need to invest in new machinery and training to effectively integrate FPCBs, rigid-flex PCBs, and ICs into their production processes.Additionally, there may be compatibility issues with existing systems and components when transitioning to these new interconnection devices. Manufacturers will need to carefully plan and test the integration of these devices to ensure a smooth transition and avoid any disruptions to the production process.In conclusion, the mainstream modeling interconnection device in the manufacturing industry is undergoing a transformation as new technologies such as FPCBs, rigid-flex PCBs, and ICs replace traditional PCBs. These new devices offer improved performance, flexibility, and efficiency, allowing manufacturers to produce higher quality products in less time. While there are challenges to overcome when implementing these new devices, the benefits they offer in terms of design flexibility, reliability, and efficiency make them a valuable addition to the production process. As technology continues to advance, it is likely that we will see even more innovative interconnection devices emerge, further revolutionizing the manufacturing industry.

Electronic component interconnection methods are essential in the manufacturing of electronic devices and systems. These methods involve the connection of various electronic components such as resistors, capacitors, transistors, and integrated circuits to create functional circuits. There are several key product categories of electronic component interconnection methods that are commonly used in the industry. These categories include soldering, wire bonding, and surface mount technology.Soldering is one of the most widely used electronic component interconnection methods. It involves the use of a soldering iron to melt solder, a metal alloy with a low melting point, and create a permanent bond between the electronic components and the circuit board. Soldering is a versatile method that can be used to connect a wide range of electronic components, from through-hole components to surface mount components. There are several types of soldering techniques, including wave soldering, reflow soldering, and hand soldering.Wave soldering is a high-volume soldering process that is commonly used in the manufacturing of printed circuit boards (PCBs). In this process, the PCB is passed over a wave of molten solder, which creates a solder joint between the electronic components and the PCB. Wave soldering is a fast and efficient method that is suitable for mass production of electronic devices.Reflow soldering is another common soldering technique that is used to connect surface mount components to PCBs. In this process, solder paste, a mixture of solder powder and flux, is applied to the pads on the PCB. The PCB is then heated in a reflow oven, which melts the solder paste and creates a solder joint between the components and the PCB. Reflow soldering is a precise and reliable method that is widely used in the electronics industry.Hand soldering is a manual soldering technique that is used for small-scale production or repair work. In this process, a soldering iron is used to melt solder and create solder joints between the electronic components and the PCB. Hand soldering requires skill and precision, but it is a versatile method that can be used for a wide range of electronic components.Wire bonding is another key product category of electronic component interconnection methods. Wire bonding is a process that is used to connect semiconductor devices, such as integrated circuits, to the leads on a PCB. In wire bonding, a thin wire is bonded to the semiconductor device and the PCB using heat and pressure. There are several types of wire bonding techniques, including ball bonding and wedge bonding.Ball bonding is a common wire bonding technique that is used to connect semiconductor devices to the PCB. In ball bonding, a small ball of wire is formed at the end of the wire using a flame or laser. The ball is then bonded to the semiconductor device and the PCB using heat and pressure. Ball bonding is a precise and reliable method that is widely used in the semiconductor industry.Wedge bonding is another wire bonding technique that is used to connect semiconductor devices to the PCB. In wedge bonding, a wedge-shaped tool is used to bond the wire to the semiconductor device and the PCB. Wedge bonding is a versatile method that can be used for a wide range of semiconductor devices.Surface mount technology (SMT) is another key product category of electronic component interconnection methods. SMT is a method that is used to connect surface mount components, such as resistors, capacitors, and integrated circuits, to the PCB. In SMT, the components are mounted directly onto the surface of the PCB using solder paste and a reflow oven. SMT is a fast and efficient method that is widely used in the electronics industry.In conclusion, electronic component interconnection methods are essential in the manufacturing of electronic devices and systems. Soldering, wire bonding, and surface mount technology are key product categories of electronic component interconnection methods that are commonly used in the industry. These methods play a crucial role in creating functional circuits and ensuring the reliability of electronic devices. By understanding the different interconnection methods and their applications, manufacturers can choose the most suitable method for their specific needs and requirements.

Electronic component interconnection is a crucial aspect of electronic design and manufacturing. It involves the physical and electrical connection of various electronic components to create functional circuits and devices. This process is essential for ensuring the proper functioning of electronic systems and devices, as well as for enabling communication between different components.There are several methods and techniques used for electronic component interconnection, each with its own advantages and limitations. In this article, we will explore the different aspects of electronic component interconnection, including the various methods used, the importance of proper interconnection, and the challenges involved in this process.Methods of Electronic Component InterconnectionThere are several methods commonly used for electronic component interconnection, each with its own unique characteristics and applications. Some of the most common methods include:1. Soldering: Soldering is one of the most widely used methods for electronic component interconnection. It involves melting a solder alloy to create a permanent bond between the components and the circuit board. Soldering is a reliable and cost-effective method, but it requires skill and precision to ensure proper connections.2. Wire bonding: Wire bonding is another common method used for interconnecting electronic components. It involves bonding thin wires to the components and the circuit board using heat and pressure. Wire bonding is often used for connecting integrated circuits (ICs) and other small components.3. Surface mount technology (SMT): Surface mount technology is a method of interconnecting electronic components by mounting them directly onto the surface of a circuit board. SMT components are smaller and lighter than traditional through-hole components, making them ideal for compact and high-density electronic devices.4. Through-hole technology: Through-hole technology involves inserting component leads through holes in a circuit board and soldering them to create a connection. This method is commonly used for larger components and components that require additional mechanical support.5. Conductive adhesives: Conductive adhesives are used for interconnecting electronic components by bonding them together using a conductive adhesive material. This method is often used for flexible circuits and other applications where soldering is not feasible.Importance of Proper InterconnectionProper interconnection of electronic components is essential for ensuring the reliable operation of electronic devices and systems. Poorly connected components can lead to electrical failures, signal degradation, and other issues that can affect the performance and functionality of the device. Some of the key reasons why proper interconnection is important include:1. Electrical performance: Proper interconnection is essential for maintaining the electrical performance of electronic circuits. Poor connections can lead to increased resistance, signal loss, and other issues that can affect the overall performance of the device.2. Reliability: Proper interconnection is crucial for ensuring the reliability of electronic devices. Loose connections, cold solder joints, and other issues can lead to intermittent failures and premature device failure.3. Signal integrity: Proper interconnection is essential for maintaining signal integrity in electronic circuits. Poor connections can lead to signal distortion, noise, and other issues that can affect the accuracy and reliability of the device.4. Thermal management: Proper interconnection is important for managing the thermal properties of electronic components. Poor connections can lead to overheating, thermal stress, and other issues that can affect the longevity and reliability of the device.Challenges in Electronic Component InterconnectionDespite the importance of proper interconnection, there are several challenges involved in the process of connecting electronic components. Some of the key challenges include:1. Miniaturization: As electronic devices become smaller and more compact, the interconnection of components becomes increasingly challenging. Miniaturized components require precise and delicate handling, making it difficult to ensure proper connections.2. High-density packaging: High-density packaging of electronic components can make it difficult to access and solder individual components. This can lead to issues such as solder bridging, tombstoning, and other soldering defects that can affect the reliability of the device.3. Thermal management: Proper thermal management is essential for ensuring the reliability of electronic components. Poorly connected components can lead to thermal issues such as overheating, thermal stress, and other issues that can affect the performance and longevity of the device.4. Compatibility: Ensuring compatibility between different components and materials is essential for proper interconnection. Incompatible materials can lead to issues such as corrosion, oxidation, and other issues that can affect the reliability and performance of the device.ConclusionElectronic component interconnection is a critical aspect of electronic design and manufacturing. Proper interconnection is essential for ensuring the reliable operation of electronic devices and systems, as well as for enabling communication between different components. There are several methods and techniques used for electronic component interconnection, each with its own advantages and limitations. Despite the challenges involved, proper interconnection is crucial for maintaining the electrical performance, reliability, signal integrity, and thermal management of electronic devices. By understanding the importance of proper interconnection and addressing the challenges involved, electronic designers and manufacturers can ensure the successful operation of electronic devices and systems.

The latest MID (Molded Interconnection Device) components are revolutionizing the way electronic devices are designed and manufactured. These components offer a wide range of benefits, including reduced size and weight, improved performance, and increased reliability. As a result, they are becoming increasingly popular in a variety of industries, from consumer electronics to automotive and medical devices.When it comes to purchasing MID molding interconnection device components, there are several different models that companies can choose from. Each model has its own advantages and disadvantages, so it is important to carefully consider which one is the best fit for your specific needs. In this article, we will explore some of the most common purchasing models for MID components and discuss the factors that companies should consider when making their decision.One of the most common purchasing models for MID components is the traditional supplier model. In this model, companies purchase components directly from a supplier who specializes in manufacturing MID components. This can be a good option for companies that do not have the expertise or resources to manufacture these components in-house. By working with a specialized supplier, companies can benefit from their expertise and experience in MID manufacturing, ensuring that they receive high-quality components that meet their specifications.Another purchasing model for MID components is the contract manufacturing model. In this model, companies work with a contract manufacturer to produce their MID components. This can be a good option for companies that want to outsource the manufacturing process but still want to have some control over the production process. By working with a contract manufacturer, companies can benefit from their manufacturing capabilities and expertise, while still retaining control over the design and specifications of the components.A third purchasing model for MID components is the hybrid model. In this model, companies work with a combination of suppliers and contract manufacturers to produce their components. This can be a good option for companies that want to take advantage of the expertise and capabilities of multiple suppliers and manufacturers, while still maintaining some control over the production process. By using a hybrid model, companies can benefit from the best of both worlds, ensuring that they receive high-quality components that meet their specifications.When choosing a purchasing model for MID components, there are several factors that companies should consider. One of the most important factors is cost. Companies should carefully consider the cost of each purchasing model, including the cost of the components themselves, as well as any additional costs such as shipping and handling. Companies should also consider the quality of the components, as well as the reliability and reputation of the suppliers and manufacturers they are working with.In addition to cost and quality, companies should also consider the lead time for production when choosing a purchasing model for MID components. Some models may offer faster production times than others, which can be important for companies that need to quickly bring their products to market. Companies should also consider the flexibility of each purchasing model, including the ability to scale production up or down as needed.In conclusion, there are several different purchasing models for MID molding interconnection device components, each with its own advantages and disadvantages. Companies should carefully consider their specific needs and requirements when choosing a purchasing model, taking into account factors such as cost, quality, lead time, and flexibility. By choosing the right purchasing model, companies can ensure that they receive high-quality components that meet their specifications, helping them to create innovative and reliable electronic devices.